Product Consultation

Your email address will not be published. Required fields are marked *

The textile industry has long been a significant contributor to environmental pollution. However, with the growing awareness of sustainable development, there is a shift towards eco-friendly textiles. One such innovation is the use of Air Through Nonwoven materials, which offer breathability and sustainability that traditional textiles cannot match. This article will explore the role of China Air Through Nonwoven in the creation of sustainable textiles, highlighting its benefits and applications.

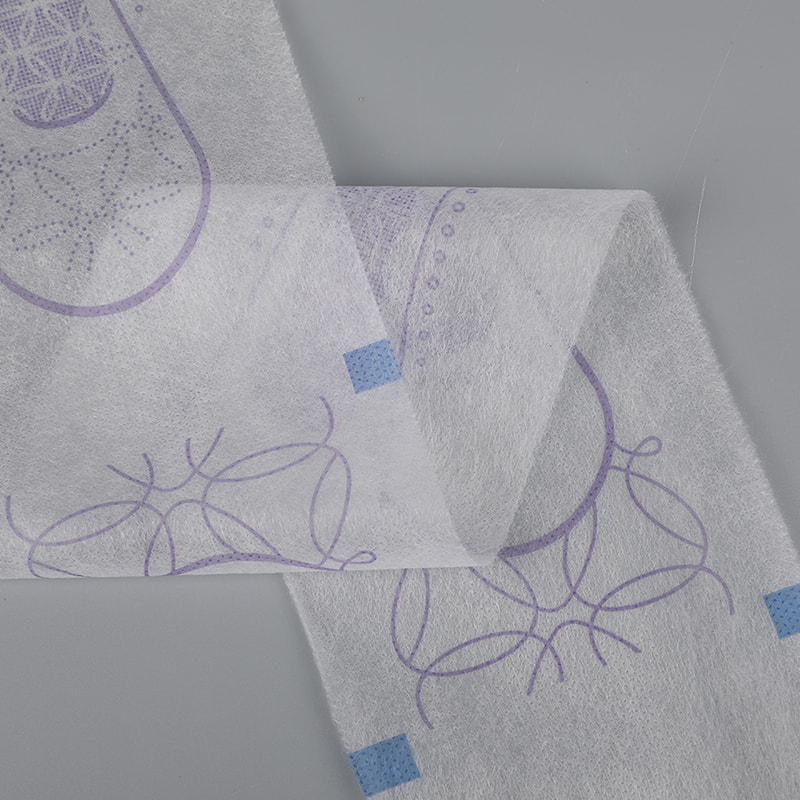

Air Through Nonwoven is a unique fabric made from a blend of natural and synthetic fibers, designed to allow air to pass through while maintaining strength and durability. This innovative material is lightweight, flexible, and has moisture-wicking properties, making it ideal for a wide range of applications.

The production of traditional textiles often involves the use of harmful chemicals and large amounts of water. In contrast, Air Through Nonwoven is produced using a more environmentally friendly process that reduces waste and reduces the carbon footprint. By choosing it, the textile industry can significantly reduce its environmental impact.

One of the key advantages of Air Through Nonwoven is its breathability. This property allows air to circulate freely, providing a comfortable and dry environment for the wearer. This is particularly beneficial in sportswear and outdoor clothing, where moisture management is crucial for performance and comfort.

The ability of Air Through Nonwoven to wick moisture away from the skin is a significant advantage in the development of eco-friendly textiles. Reducing the need for chemical treatments to enhance moisture absorption, contributes to a cleaner and more sustainable textile production process.

Traditional textiles often require frequent replacement due to wear and tear. However, Air Through Nonwoven is designed to be highly durable, reducing the need for frequent replacements and contributing to a more sustainable textile lifecycle.

Custom Nonwoven Fabric Medical is not limited to clothing. Its versatility makes it suitable for a range of applications, including medical textiles, filtration systems, and even construction materials. By incorporating it into these industries, we can further promote sustainable practices and reduce environmental impact. The production of it can also contribute to the growth of local economies. By sourcing natural fibers from local suppliers, the textile industry can support local farmers and create jobs in rural areas.

The use of Air Through Nonwoven in textiles can help reduce waste in the fashion industry. Its durability and longevity mean that garments made from this material can last longer, reducing the need for frequent replacements and the associated waste.

One of the significant benefits of Air Through Nonwoven is its potential for biodegradability. By using natural fibers in its production, Air Through Nonwoven can break down more easily at the end of its lifecycle, reducing the environmental impact of textile waste.

The unique properties of Polypropylene Fabric Nonwoven Manufacturers open up new possibilities for textile design. Designers can experiment with new forms and structures, creating innovative and sustainable garments that are both functional and fashionable.

As the world moves towards a more sustainable future, the role of Air Through Nonwoven in eco-friendly textiles will only grow. By continuing to innovate and develop new applications for this material, we can create a more environmentally friendly textile industry that meets the needs of both people and the planet.

The role of Air Through Nonwoven in eco-friendly textiles is a testament to the power of innovation in creating sustainable solutions. By embracing this material, the textile industry can reduce its environmental impact, support local economies, and provide consumers with high-quality, durable, and comfortable products. As we continue to explore the potential of Air Through Nonwoven, we can look forward to a future where sustainability is at the heart of textile production.

Exploring the Versatility of Air Through Nonwoven

Aug 23,2024

The Role of a PE Breathable Film Supplier in the Medical Industry

Sep 06,2024Your email address will not be published. Required fields are marked *

HENGYAO

HENGYAO

NEW MATERIAL