Product Consultation

Your email address will not be published. Required fields are marked *

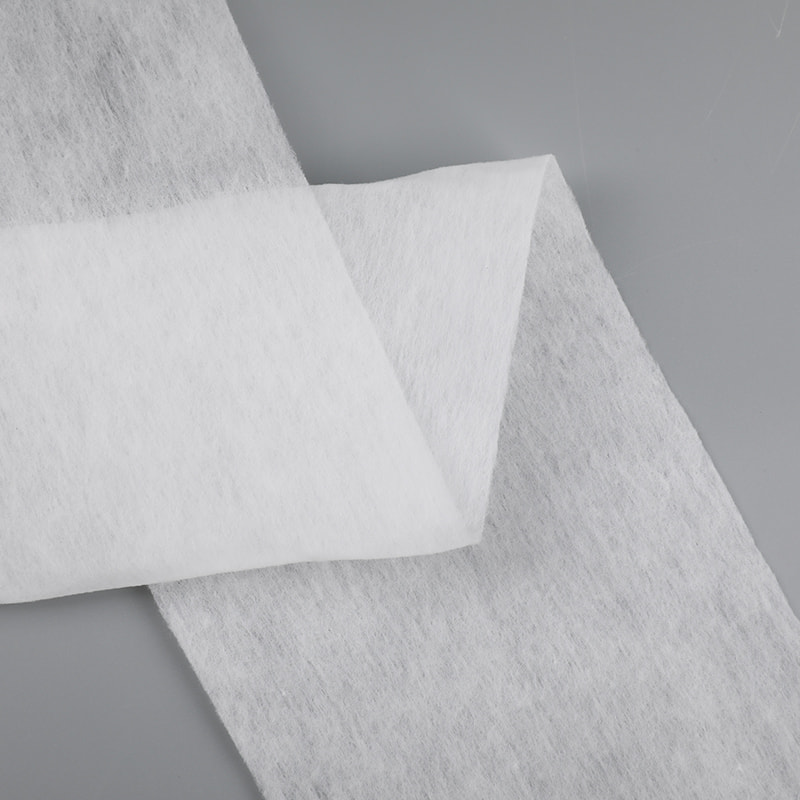

The nonwoven industry has witnessed remarkable growth and innovation in recent years, driven by the demand for versatile and sustainable materials. Among these advancements, SS Nonwoven has emerged as a game-changer, offering enhanced strength and flexibility for various applications. This article explores the features, advantages, and applications of SS Nonwoven, highlighting its impact on the nonwoven industry and beyond.

Understanding SS Nonwoven SS Nonwoven is a type of nonwoven fabric that is made using a specialized production process called spunbond meltblown spunbond (SMS). It consists of a combination of two spunbond layers and one meltblown layer, resulting in a fabric with improved strength, durability, and versatility. The spunbond layers provide the fabric with strength and stability, while the meltblown layer adds filtration properties and enhances the fabric's softness.

Features and Advantages of SS Nonwoven SS Nonwoven offers several key features and advantages, making it a preferred choice in various industries: Strength and Durability: The combination of spunbond and meltblown layers gives SS Nonwoven exceptional strength and tear resistance, making it suitable for demanding applications. Softness and Comfort: The meltblown layer enhances the fabric's softness, ensuring a gentle and comfortable touch against the skin. Breathability: SS Nonwoven allows air to pass through, maintaining airflow and reducing moisture buildup, making it ideal for applications that require breathability, such as hygiene products. Fluid and Particle Filtration: The meltblown layer in SS Nonwoven provides excellent filtration properties, allowing it to effectively block particles and liquids while remaining breathable. Versatility: SS Nonwoven can be produced in various weights, colors, and finishes, offering flexibility for different applications across industries.

Applications of SS Nonwoven SS Nonwoven finds extensive use in a wide range of industries due to its unique properties: Hygiene Products: SS Nonwoven is widely used in the manufacturing of diapers, sanitary napkins, and adult incontinence products. Its strength, softness, and breathability make it an ideal choice for these applications. Medical and Healthcare: The fabric's filtration properties and high strength make it suitable for surgical gowns, drapes, face masks, and wound dressings, providing protection and comfort to patients and healthcare professionals. Automotive: SS Nonwoven is used in the automotive industry for applications such as car interiors, insulation, and soundproofing, thanks to its durability, softness, and ability to reduce noise. Construction: The fabric's strength and water resistance make it ideal for construction applications such as roofing membranes, insulation, and geotextiles. e. Agriculture: SS Nonwoven is used for crop covers, greenhouse shading, and weed control due to its durability, breathability, and resistance to ultraviolet radiation.

Sustainability and SS Nonwoven SS Nonwoven contributes to sustainability efforts in several ways: Recyclability: Many variants of SS Nonwoven can be recycled, reducing the reliance on virgin materials and minimizing waste. Reduced Chemical Usage: The production process of SS Nonwoven requires fewer chemicals compared to traditional textile manufacturing, minimizing the environmental impact. Energy Efficiency: The production of SS Nonwoven consumes less energy compared to woven textiles, reducing the carbon footprint associated with the manufacturing process. Lightweight Nature: The lightweight nature of SS Nonwoven reduces transportation costs and emissions, further contributing to sustainability goals.

SS Nonwoven has revolutionized the nonwoven industry with its enhanced strength, durability, and versatility. As a result of its unique production process combining spunbond and meltblown layers, SS Nonwoven offers exceptional features such as strength, softness, breathability, and filtration, making it an ideal choice for numerous applications across various industries. Moreover, SS Nonwoven's contribution to sustainability through recycling, reduced chemical usage, and energy efficiency positions it as a promising solution in the pursuit of environmentally friendly materials. The continued advancement and adoption of SS Nonwoven highlight its potential to drive further innovation and sustainability in the nonwoven industry and beyond.

Advancing Baby Diaper Innovation with Wet PE Breathable Printing Film Back Sheet Film

Jul 19,2023

Enhancing Comfort and Performance: The Evolution of Top Sheet Nonwoven in Various Applications

Jul 20,2023Your email address will not be published. Required fields are marked *

HENGYAO

HENGYAO

NEW MATERIAL